The Split Set Rock Bolt is a versatile and reliable rock reinforcement method that has found widespread application in various industries, particularly in mining and tunneling operations. This article will delve into the details of where the Split Set Rock Bolt can be used, highlighting its key features, advantages, and specific applications.

Introduction To The Split Set Rock Bolt

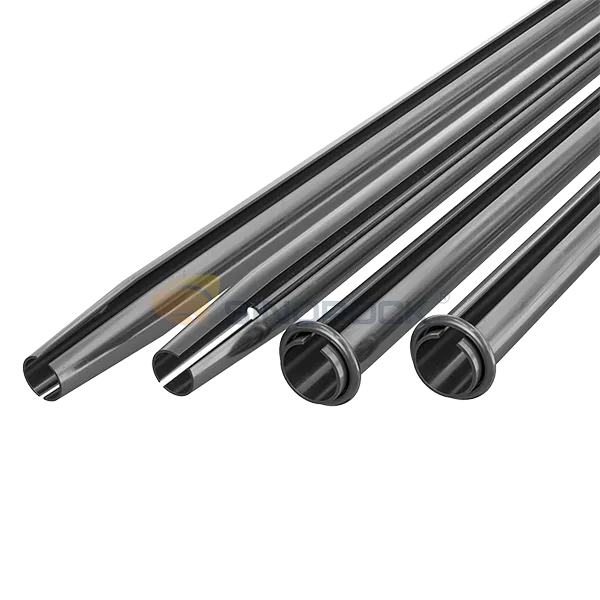

The Split Set Rock Bolt is a rock reinforcement system renowned for its simplicity, ease of installation, and exceptional load-bearing capacity. It is designed to provide support and stability in underground environments where rock stability is crucial. This innovative system comprises two main components: a high-strength steel anchor rod and a matching domed bearing plate.

The Anchor Rod

The anchor rod is the core component of the Split Set Rock Bolt. It is typically made from high-strength steel and features a longitudinal slot along its length. This slot plays a pivotal role in the rock bolting process by allowing the rod to compress and grip the surrounding rock, ensuring a secure anchoring system.

The Domed Bearing Plate

Accompanying the anchor rod is the domed bearing plate. This component evenly distributes loads applied to the bolt, enhancing its load-bearing capacity and ensuring the stability of the surrounding rock.

Applications Of The Split Set Rock Bolt

The versatility of the Split Set Rock Bolt makes it suitable for a wide range of applications. Below, we explore various scenarios where this rock reinforcement system can be effectively employed.

A. Mining Operations

Mining operations, whether in surface mines or underground mines, frequently encounter unstable rock formations. The Split Set Rock Bolt is an invaluable tool in these environments. It provides roof and sidewall support, reducing the risk of roof collapses and enhancing the safety of miners.

a. Underground Mining

In underground mining, tunnels and shafts are often exposed to geological stresses and the potential for roof falls. Split Set Rock Bolts are installed to reinforce the surrounding rock, preventing dangerous collapses and ensuring a stable working environment for miners.

b. Surface Mining

Surface mining operations, such as open-pit mining, also benefit from Split Set Rock Bolts. These bolts can be used to stabilize high walls and prevent rockfalls, improving safety and efficiency in open-pit operations.

B. Tunneling Projects

Tunnel construction involves excavating through various types of rock and soil. The Split Set Rock Bolt is commonly employed in tunneling projects to reinforce tunnel walls and roofs, reducing the risk of rock or soil collapse.

a. Road And Rail Tunnels

In the construction of road and rail tunnels, Split Set Rock Bolts are used to provide immediate support and long-term stability. They help maintain the integrity of the tunnel structure, ensuring safe passage for vehicles and trains.

C. Civil Engineering

Beyond mining and tunneling, Split Set Rock Bolts find application in civil engineering projects where rock reinforcement is necessary.

a. Slope Stabilization

In areas prone to landslides or rockfalls, Split Set Rock Bolts can be employed to stabilize slopes and prevent hazardous events. They provide effective support for retaining walls and embankments.

b. Foundation Support

In construction projects that involve excavations near rock formations, such as building foundations, Split Set Rock Bolts can be used to reinforce the surrounding rock and prevent foundation settling or failure.

D. Geotechnical Engineering

Geotechnical engineers often utilize Split Set Rock Bolts for soil and rock stabilization in various applications.

a. Dams And Reservoirs

In dam construction, where the stability of the structure is paramount, Split Set Rock Bolts may be employed to reinforce the surrounding rock and prevent potential issues related to seepage or instability.

b. Soil Nailing

Soil nailing is a technique used to stabilize and reinforce soil slopes. The Split Set Rock Bolt system can be adapted for this purpose, enhancing the strength and stability of slopes and embankments.

Advantages Of Using Split Set Rock Bolts

Understanding the numerous advantages of the Split Set Rock Bolt system further emphasizes its versatility and suitability for various applications:

A. Quick Installation

Split Set Rock Bolts can be rapidly installed, reducing downtime and project delays. This efficiency is particularly valuable in mining and tunneling operations with tight schedules.

B. High Load-Bearing Capacity

These rock bolts exhibit exceptional load-bearing capacity, making them capable of withstanding significant geological stresses and providing reliable support.

C. Minimal Maintenance

Once installed, Split Set Rock Bolts require minimal maintenance. This long-term stability ensures cost-effective solutions for various projects.

D. Versatility

The adaptability of Split Set Rock Bolts to different rock types and conditions makes them versatile tools in a wide range of industries.

E. Enhanced Safety

The primary function of Split Set Rock Bolts is to enhance safety by stabilizing rock and soil formations, reducing the risk of collapses and accidents.

Conclusion

The Split Set Rock Bolt is a fundamental component in the toolkit of professionals working in mining, tunneling, civil engineering, and geotechnical engineering. Its straightforward design, high load-bearing capacity, and versatility make it an indispensable choice for reinforcing rock and soil formations in various applications.

Whether securing underground mines, stabilizing tunnel walls, or fortifying slopes in civil engineering projects, the Split Set Rock Bolt consistently delivers the stability and safety needed to tackle the most challenging geological conditions. Its importance cannot be overstated, as it continues to play a pivotal role in ensuring the success and safety of projects across multiple industries.