Introduction

Anchor rod is an important component in tunnel support. As a tension member that penetrates deep into the surrounding rock, one end of it is connected to the initial support structure, and the other end is consolidated with the surrounding rock through the anchoring section. Anchors can connect and fix the surrounding rocks around the tunnel together, thereby improving the self-supporting ability of the surrounding rocks.

Expandable rock bolts offer a robust mechanism to fortify rock formations prone to instability and bursts. This article delves into the structural composition, anchorage mechanism, performance characteristics, applicable conditions, and construction technology of expandable rock bolts.

1. Structural Composition

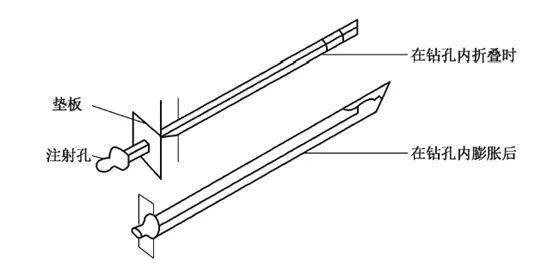

Expandable rock bolts represent a fusion of engineering precision and robust materials. Their structural composition comprises three main components: a steel tubular anchor, a mounting arm, and a pneumatic high-pressure water pump. The anchor rod body, crucial for anchoring efficacy, is meticulously crafted from a steel pipe with a 2mm thickness and a 41mm diameter, ensuring durability and resilience. Through a meticulous folding process, the outer diameter of the anchor rod is reduced to 26mm, optimizing its compatibility with various geological formations. The sealing integrity is guaranteed through welded seams and reinforced with a flange plate at the base, bolstering stability and load-bearing capacity (see Figure 1).

2. Anchorage Mechanism

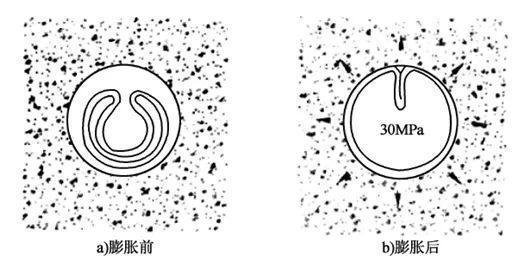

The efficacy of expandable rock bolts hinges on their anchorage mechanism, which capitalizes on friction and mechanical self-locking forces. Unlike traditional anchors that rely solely on adhesion or friction, expandable rock bolts exhibit a dynamic anchoring process adaptable to diverse stratigraphic conditions. In hard rock formations, the anchoring mechanism unfolds with remarkable precision. As the anchor bolt expands, exerting a pressure of 30MPa, it seamlessly conforms to irregularities in the borehole, compressing the surrounding rock mass. Upon release of the set pressure, a tightened “shrink sleeve” effect ensues, enhancing pullout resistance and fortifying stability. Notably, even in the face of joint deformations in surrounding rock formations, the anchoring strength amplifies, underscoring the adaptability and resilience of expandable rock bolts (see Figure 2).

3. Performance Characteristics

The distinctive features of expandable rock bolts delineate a paradigm shift in structural reinforcement methodologies. A comprehensive understanding of these characteristics elucidates their unparalleled efficacy in contemporary construction endeavors:

- Simplicity of Installation: The installation process is straightforward and less reliant on the installer’s expertise, ensuring consistent quality across projects.

- Versatile Embedding Methods: Manual, semi-mechanized, or fully mechanized embedding methods yield uniform results, catering to diverse construction exigencies.

- Rapid Deployment: With a burying speed of 20 to 30 anchor rods per hour per worker, expandable rock bolts expedite construction timelines without compromising quality.

- Automated Pressure Control: The integration of high-pressure water pumps ensures precise expansion pressure control, optimizing the load-bearing capacity of each anchor rod.

- Adaptability to Stratigraphic Variability: From sand and clay to the sturdiest granite, expandable rock bolts demonstrate unparalleled adaptability, transcending geological constraints.

- Resilience to Joint Deformations: The bearing capacity remains unaffected by surrounding rock joint deformations, exhibiting heightened anchoring strength amidst structural perturbations.

- Scalability: Anchor rods of varying lengths, extending up to 12m, can be manufactured without altering installation procedures, offering flexibility in construction planning.

- Cost Efficiency: While the initial investment may be higher, the low installation costs render expandable rock bolts economically viable over the long term.

4. Applicable Conditions

The versatility of expandable rock bolts renders them indispensable in mitigating rock instability across a spectrum of conditions. Tailored construction measures optimize their efficacy in diverse scenarios:

- Rockfall Mitigation: For instances of rockfall without severe damage, expandable rock bolts suffice, with anchor lengths doubling the blasting cycle footage to stabilize subsequent rock cycles, supplemented by ordinary pads.

- Moderate to Severe Rock Bursts: In scenarios of moderate to severe rock bursts, yield-type expandable rock bolts are deployed, with anchor lengths doubling the blasting cycle. Addition of wooden boards mitigates displacement and fracture risks, bolstering stability.

- Severe Rock Bursts: Intense rock bursts necessitate a multifaceted approach, combining yield-type expandable rock bolts with steel mesh and shotcrete for comprehensive reinforcement.

5. Construction Technology

The installation process of expandable rock bolts epitomizes simplicity without compromising efficacy. A step-by-step elucidation of the construction technology underscores its accessibility and efficiency:

- Drilling: Holes with diameters ranging from 32mm to 39mm, preferably 38mm, are drilled with precision, laying the foundation for anchor deployment.

- Anchor Insertion: With a chuck affixed to the lower end of the expandable rock bolt, it is inserted into the drilled hole, positioning it for expansion.

- Expansion: Activation of the high-pressure water pump initiates the expansion process, with the concave section steel pipe expanding under hydraulic pressure, ensuring a secure lock between the anchor rod and rock mass.

- Pressure Control: Automated pressure control mechanisms halt pump operation upon reaching specified expansion pressure, optimizing anchorage integrity.

- Stabilization Enhancements: In scenarios of intense rock bursts, the addition of wooden or rubber pads fortifies anchor resilience, enabling it to withstand displacement induced by rock surface cracking.

While the expandable rock bolt’s design enables expansion and high tensile force endurance at 7MPa, on-site variability necessitates a prudent approach. Controlling water injection pressure within the 15-20MPa range ensures optimal performance across diverse geological conditions.

Conclusion

Expandable rock bolts epitomize a convergence of innovation and practicality, revolutionizing structural reinforcement methodologies across diverse geological contexts. From their meticulously engineered structural composition to their dynamic anchorage mechanisms and versatile deployment, expandable rock bolts stand as stalwarts of stability in contemporary construction practices. If you are at all curious about expandable rock bolts or have a specific request or need, please do not hesitate to reach out to us at sinorock@sinorockco.com.