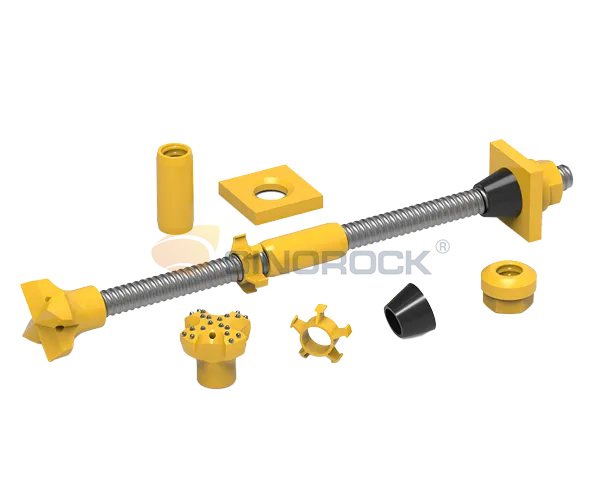

In the booming construction industry, self-drilling anchor bolts are widely used due to their unique advantages. However, at the same time, many problems have gradually emerged. While it is important to select suitable self-drilling anchor bolts, how to extend their service life has also become a crucial point that cannot be ignored in engineering projects. A scientifically designed and precisely installed self-drilling anchor bolt can undoubtedly provide solid and long-term support for engineering construction. However, if we want to ensure the smooth progress of engineering construction without interference from the premature failure of self-drilling anchor bolts, it is necessary to ensure that they have a sufficiently long service life.

Therefore, it is extremely important to explore effective strategies to extend their service life. Before delving into specific methods, let’s first trace back to the root to understand the fundamental reasons for extending the service life of self-drilling anchor bolts, and figure out why it is imperative to extend the service life of self-drilling anchor bolts in engineering projects.

Why extend the service life of self-drilling anchor bolts?

- Enhance project cost-effectiveness – Extending the service life can achieve long-term cost savings by reducing the frequency of maintenance and repair costs.

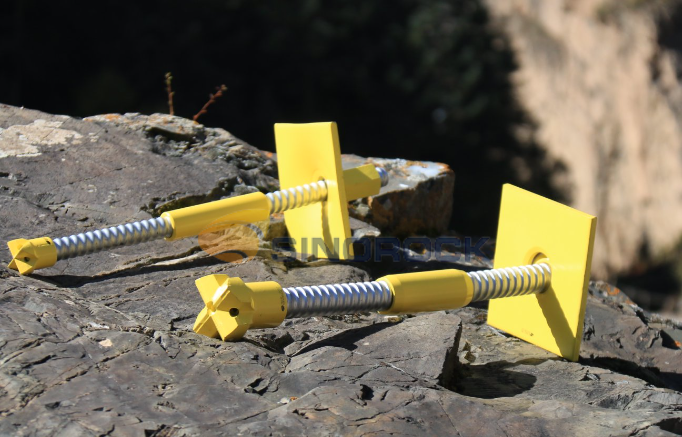

- Minimize construction interference – In ongoing projects such as tunnels and slopes, the replacement of self-drilling anchor bolts may cause project interruptions. Extending the service life can reduce the need for such interventions, thus avoiding project delays and additional costs caused by construction halts.

- Meet the needs of optimized design and installation – Through a systematic analysis of key factors affecting the service life, such as corrosion and load over-limit, engineers can improve the material selection, structural design, and installation process of self-drilling anchor bolts in a targeted manner, directly enhancing the safety and durability of the system.

- Ensure long-term safety performance of the project – The service life of self-drilling anchor bolts is directly related to the period during which they can maintain the necessary load-bearing capacity. During the period from the installation of the self-drilling anchor bolt to the time when its effectiveness decreases to an unacceptable level, if the load-bearing capacity decreases due to corrosion, load over-limit, or structural damage, it will pose a threat to the safety of the project. Extending the service life essentially means maintaining the continuous and stable support capacity of the self-drilling anchor bolt for the building structure. By extending the service life, the long-term safety performance of the project can be ensured.

It can be seen that extending the service life of self-drilling anchor bolts is of vital importance. So, how exactly can we extend it? Before exploring specific extension methods, it is necessary to have an in-depth understanding of the relevant factors affecting the service life of self-drilling anchor bolts, which will lay the foundation for subsequent discussions. Next, let’s explore these factors in depth.

Factors affecting the service life of self-drilling anchor bolts

The service life of self-drilling anchor bolts can generally reach about 20 years, but the actual service cycle is affected by multiple factors. By analyzing key influencing factors (such as environmental factors, grouting material factors, and protective layer factors), manufacturers can develop targeted protective strategies, thereby significantly improving the service life of self-drilling anchor bolts.

Failure to Implement Maintenance and Inspection Measures

The timeliness and effectiveness of maintenance and inspection directly affect the service life of self-drilling anchor bolts:

- Lack of Regular Inspections: Failing to regularly check for signs of aging, cracks, and corrosion in the self-drilling hollow anchor bar may lead to the accumulation of hidden hazards, eventually causing structural failure.

- Inadequate Maintenance: Not conducting regular cleaning of the anchor system and lubrication of key components may result in issues such as debris accumulation and component jamming.

- Delayed Fault Response: Failing to promptly repair or replace damaged components or those with degraded performance may exacerbate problems, such as the spread of local corrosion and the continuous decline in structural load-bearing capacity.

Protective layer factors

Applying a protective layer on the surface of self-drilling anchor bolts can effectively improve their service life. As a cement body wrapped around the self-drilling anchor bolt, the protective layer forms a physical isolation barrier, effectively blocking direct contact between external corrosive media, moisture, and the self-drilling anchor bolt, thus playing an effective protective role.

Environmental factors

- Corrosion factors – In an environment containing corrosive substances such as chemicals, salt water, and acidic soil, an electrochemical reaction will occur on the surface of self-drilling anchor bolts, leading to chemical erosion. This chemical erosion not only causes a loss of the material cross-sectional area but also forms micro-cracks inside the anchor bolts, reducing the load-bearing capacity.

- Temperature fluctuations – Severe temperature changes can cause expansion and contraction deformation of the self-drilling anchor bolt material. When the temperature fluctuation exceeds the elastic limit of the material, it will cause cracking of the protective layer and a decrease in the load-bearing capacity.

- Humidity effects – In a dry environment, the service life of self-drilling anchor bolts can be 2 – 3 times longer than that in a humid environment. When the environmental humidity exceeds the critical relative humidity, a corrosion reaction will form on its surface, thereby weakening the mechanical properties and structural integrity of the material.

How to extend the service life of self-drilling anchor bolts?

Proactive Maintenance and Inspection Protocols

- Scheduled Inspection Regimens: Conduct routine checks to identify early signs of aging, cracks, or corrosion in self-drilling hollow anchor bars. Implement a structured inspection schedule to prevent structural failure.

- Preventive Maintenance Practices: Regularly clean the anchor system to remove debris, soil, or corrosive deposits that may accumulate during operation. Lubricate key moving components to ensure smooth functionality.

- Rapid Fault Resolution: Establish a responsive maintenance workflow to address damages or performance degradation immediately. Replace corroded or cracked components promptly to avoid issue escalation.

Environmental Mitigation Strategies

To safeguard self-drilling hollow anchor bars from environmental erosion, select corrosion-resistant materials or apply composite anti-corrosion coatings to block chemical media and isolate components from the external environment.

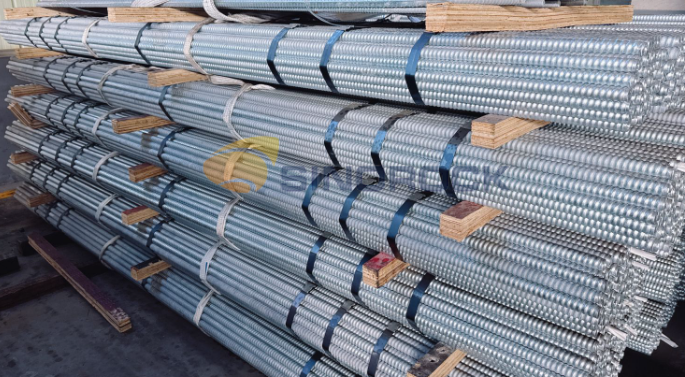

- Hot-Dip Galvanizing Anti-Corrosion Measures: Hot-dip galvanizing, as an effective metal anti-corrosion method, plays an important role in the protection of self-drilling anchor bolts. Steel products are first cleaned and activated, and then immersed in molten zinc liquid. Through the interaction of atoms, an iron-zinc alloy layer is formed on the surface. This alloy layer is dense, uniform, and firmly adheres to the steel surface, avoiding direct environmental erosion, fundamentally inhibiting electrochemical corrosion.

- Epoxy Coating Anti-Corrosion Measures: Epoxy resin powder electrostatic spraying creates a robust anti-corrosion coating for self-drilling anchor bolts. In factory settings, epoxy powder is evenly applied via electrostatic technology and cured to form a protective barrier, resisting oxygen, chloride ions, and water penetration.It excels in humid environments, and seawater-exposed areas, making it widely used in industrial projects.

- Dual Anti-Corrosion Measures: Dual anti-corrosion combines hot-dip galvanizing and epoxy coating: first galvanizing, then spraying epoxy. This enhances anti-corrosion performance and extends protection life, adapting to various corrosive environments. It is widely used in critical infrastructure—water conservancy projects, underwater tunnels, —exposed to groundwater or seawater, ensuring long-term durability.

Protective Layer Monitoring

Regularly inspect protective layers for cracks, or damage, especially in high-stress or harsh environments. Repair compromised layers promptly to maintain their isolation and protective functions.

Conclusion

Extending the service life of self-drilling anchor bolts has many advantages. However, there are also many factors affecting their service life, including environmental factors, grouting material factors, and protective layer factors. By carefully analyzing and fully understanding these factors and taking targeted measures, the service life of self-drilling anchor bolts can be extended to the maximum extent, ensuring long-term stability and reliability in engineering construction.

The Sinorock, as a professional manufacturer of self-drilling anchor bolts, has accumulated years of rich experience in providing comprehensive geotechnical engineering services. If you have any requirements or questions about self-drilling anchor bolts, please feel free to contact us at sinorock@sinorockco.com.