Self drilling rock bolts are vital components in the construction industry, especially in projects that involve tunnel construction, slope stabilization, and foundation reinforcement. As demand for these essential tools increases, so does the number of manufacturers offering self drilling rock bolts. However, not all manufacturers are created equal, and selecting a reliable supplier is crucial to the success of your project. Poor-quality rock bolts can lead to project delays, safety risks, and increased costs, making it essential to choose a trustworthy and reputable manufacturer.

1. Authenticity of the Manufacturer: Trust in the Source

When selecting a self drilling rock bolt manufacturer, one of the first things to assess is the authenticity of the company. The reliability and legitimacy of the manufacturer directly impact the quality of the products they produce. Ensuring that you partner with a genuine supplier is critical for achieving the highest performance standards in your construction projects.

Real Factory and Genuine Products

A trustworthy manufacturer should have a verifiable production facility that meets industry standards. Ensure that the supplier operates a real factory that adheres to regulations and has the necessary certifications for quality and safety. Authenticity can also be assessed through the manufacturer’s transparency regarding their operations. A legitimate company will openly share information about their factory location, production capacity, and processes. For example, Sinorock, a well-established manufacturer of self-drilling rock bolts, operates genuine factories in Luoyang and Changzhou, China. Their locations are strategically positioned to ensure efficient product availability and timely shipments.

A credible manufacturer provides not only high-quality products but also fosters trust by offering transparent business practices. Without authenticity, there is a risk of receiving substandard products that could jeopardize the success of your project. Ensuring the authenticity of your supplier protects both your investment and the safety of the workers involved in the project.

Authoritative Certifications

Certifications are a clear indication of a manufacturer’s commitment to producing high-quality products that meet international standards. Industry certifications such as ISO (International Organization for Standardization) and CE (Conformité Européenne) confirm that the manufacturer’s operations and products comply with established quality management systems and safety standards. A reputable manufacturer will proudly display these certifications to reinforce their credibility.

For example, Sinorock holds several prestigious certifications, including ISO 9001 and CE, which confirm their adherence to international standards. These certifications are not just formalities; they represent a rigorous commitment to producing products that meet the highest standards of quality, safety, and performance in the construction industry.

2. Quality Control System: The Backbone of Reliability

A strong quality control (QC) system is essential to ensuring that self-drilling rock bolts are produced to exacting standards. Quality control guarantees that each batch of products meets the required specifications, reducing the likelihood of defects and ensuring the safety and longevity of the bolts in construction projects.

Incoming Inspection

The first step in quality control involves inspecting the raw materials before production begins. A reliable manufacturer will perform thorough checks on incoming materials, ensuring they meet the necessary quality standards before being processed. Only materials that pass the initial inspection will be used in the production of self-drilling rock bolts, ensuring that each bolt is made with high-quality materials from the outset.

A manufacturer committed to quality will have a clearly defined incoming inspection process. They should use a proper sampling ratio and check every aspect of the materials, including physical properties and potential defects. This step is vital to prevent any subpar materials from being incorporated into the final product.

Process Inspection

Process inspection is a critical component of any robust quality control system. During the manufacturing process, inspections should be carried out at various stages to detect and address any issues early on. Many reputable manufacturers implement a “three-inspection system” that includes self-inspection, mutual inspection, and special inspection. This multi-layered approach ensures that potential defects are caught early, reducing the likelihood of defective products reaching customers.

During process inspection, the manufacturer will focus on factors such as the precision of machining, thread integrity, and weld quality (if applicable). By maintaining strict quality control at this stage, manufacturers can ensure that every self-drilling rock bolt meets technical specifications and adheres to industry standards.

Outgoing Inspection

Once the products are manufactured, they undergo outgoing inspection before being shipped to customers. This final inspection step ensures that the finished products are in optimal condition and ready for use. The outgoing inspection involves checking product dimensions, weight, packaging integrity, and the correct labeling and documentation. Reputable manufacturers will also take photographs of the products and packaging to document the condition of the items before they leave the factory. This ensures that any potential issues can be traced back to the source if problems arise later.

An effective outgoing inspection process is essential for ensuring that customers receive only the highest-quality products. It also provides added security for both the manufacturer and the buyer, as detailed inspection records can help resolve disputes if any issues occur after delivery.

3. Customer Service: A Key to Long-Term Relationships

Customer service is not just about resolving problems when they occur—it’s about building a long-lasting relationship with customers by offering comprehensive support throughout the entire purchasing journey. From pre-sale inquiries to post-sale assistance, a manufacturer’s level of customer service can have a significant impact on your overall experience.

Pre-sale, In-sale, and After-sale Support

A reliable manufacturer offers excellent support at every stage of the customer journey. In the pre-sale phase, a trustworthy supplier will assist customers in selecting the most suitable self-drilling rock bolts based on the project’s requirements. This support might include offering detailed product specifications, performance data, and helping customers understand which type of bolts would be most effective in specific geological conditions.

During the sale, a reputable manufacturer will ensure timely delivery and provide clear communication about order status, shipment tracking, and any potential delays. However, the most important aspect of customer service is after-sale support. After the product is delivered, the manufacturer should offer a solid support program to address any issues that arise. This includes technical assistance, troubleshooting, and ensuring that any problems with installation or product performance are promptly addressed.

For example, Sinorock offers exceptional after-sale services, providing comprehensive support through a dedicated customer service team. Their services include everything from installation guidance to troubleshooting, ensuring that customers can maximize the effectiveness and lifespan of their self-drilling rock bolts.

Customized Service Options

Some manufacturers also offer customized services to meet the unique needs of individual projects. These services may include adjusting the specifications of the products, offering personalized installation training, or providing specific testing procedures to meet particular project demands. Customized services are particularly valuable when working on large-scale or complex construction projects, where standard solutions may not be sufficient.

By offering these specialized services, a manufacturer can help streamline project execution, reduce installation time, and improve overall project efficiency. This customer-centric approach ensures that your needs are met with precision and care, increasing the likelihood of a successful project outcome.

4. Product Diversity: Meeting the Needs of Every Project

A trustworthy self-drilling rock bolt manufacturer should offer a wide range of products that can cater to various project requirements. The ability to choose from a diverse selection of products ensures that you can find the perfect solution for any construction challenge, whether you’re reinforcing tunnels, stabilizing slopes, or securing foundations.

Types of Self-Drilling Rock Bolts

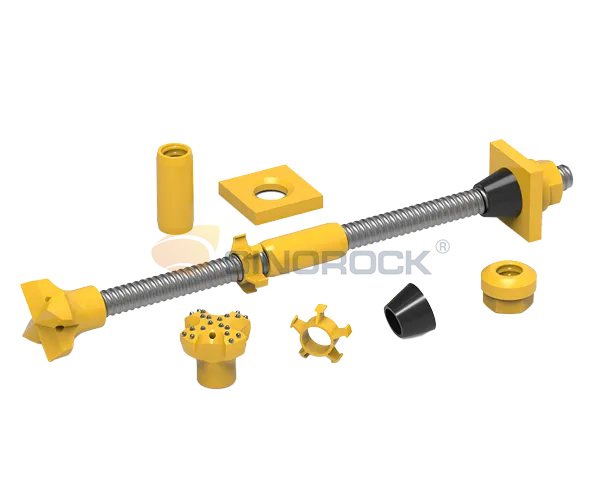

Self-drilling rock bolts are available in various sizes, thread types, and configurations. A reputable manufacturer should offer a broad selection of options to meet the diverse needs of their clients. For instance, Sinorock provides a wide array of self-drilling rock bolts, including R-thread and T-thread systems in various sizes, from R25 to T200. This range of options allows customers to select the most suitable bolts for their specific geological conditions and engineering requirements.

Specialized Drill Bits

In addition to self-drilling rock bolts, a quality manufacturer will also provide specialized drill bits designed to meet the demands of different geological conditions. Sinorock, for example, offers a range of drill bits such as clay drill bits, ECC drill bits, and EYY drill bits, each optimized for different types of rock formations. This variety enhances drilling efficiency, reduces project timelines, and improves the cost-effectiveness of the project.

By offering a diverse range of products and customization options, a trustworthy manufacturer ensures that every project is equipped with the right tools for the job, improving both the speed and quality of construction.

Conclusion: Making an Informed Choice

Choosing the right self drilling rock bolt manufacturer is essential to the success of your construction project. By considering factors such as authenticity, quality control, customer service, and product diversity, you can ensure that you select a manufacturer that meets the highest standards of reliability and quality. Whether you are working on tunnel construction, slope stabilization, or foundation reinforcement, partnering with a trustworthy supplier like Sinorock will help you secure the best products for your project, reducing risks and enhancing overall efficiency.

Always prioritize quality over price when selecting self drilling rock bolts. While it may be tempting to go with the cheapest option, cutting corners on essential construction materials can lead to costly delays, safety hazards, and project failures. By choosing a manufacturer that offers high-quality products and outstanding support, you can ensure the long-term success and safety of your construction projects.