With the continuous deepening of modern urban underground space development, deep foundation pit projects have become a key link in high-rise buildings, underground transportation hubs, and other projects. The reliability of its support technology directly affects project safety and urban stability. Faced with complex geological and construction challenges, traditional support methods have gradually shown their shortcomings.

At the same time, self-drilling anchor bolts stand out with innovative technology and become the preferred solution for deep foundation pit support. This article mainly analyzes the application advantages of self-drilling anchor bolts in deep foundation pit support. First, let’s understand the basic concepts and types of deep foundation pits.

The Concept and Common Types of Deep Foundation Pits

A deep foundation pit refers to earth excavation, support, and dewatering projects for pits with an excavation depth of more than 5 meters; or foundation pit projects with an excavation depth of fewer than 5 meters but complex geological conditions, the surrounding environment, and underground pipelines, or those that affect the safety of adjacent buildings.

In actual projects, common types of deep foundation pits include pile-wall supported foundation pits, diaphragm wall foundation pits, and soil nail wall foundation pits. Different types of deep foundation pits are suitable for different geological conditions and surrounding environments.

Their design and construction need to consider various factors comprehensively. However, regardless of the type, they all need to meet the basic requirements of deep foundation pit support, mainly including the following four aspects.

Basic Requirements for Deep Foundation Pit Support

Ensure that the support structure has reliable earth-retaining capacity to maintain the stable state of the foundation pit slope and prevent soil collapse and safety accidents.

Guarantee the safety of adjacent buildings, roads, and underground pipelines, and avoid damage to surrounding facilities caused by soil deformation, settlement, and other problems.

Ensure the smooth progress of construction above the groundwater level through scientific and reasonable drainage and dewatering measures.

In the process of support structure design, give priority to the protection requirements of the surrounding environment, then meet the construction requirements of the underground structure of this project, and at the same time take into account the economy, strive to reduce the cost, and facilitate construction.

Of course, it is not easy to meet these requirements. The deep foundation pit support project also faces many difficulties in actual progress. Let’s take a look at what these difficulties are.

Difficulties in Deep Foundation Pit Support

Complex cross-processes and high coordination difficulty

The processes of foundation concrete pouring, earth excavation, pile foundation construction, and dewatering in adjacent construction sites are interrelated and restrict each other, significantly increasing the difficulty of construction coordination. If not properly coordinated, it is likely to cause delays in the construction period and quality hidden dangers.

Limited site, long construction period, and great threats from environmental factors

The construction site of deep foundation pits has limited space and the construction period is often long. Stacking heavy objects on the top of the foundation pit or encountering adverse weather such as rain may pose a threat to the stability of the foundation pit.

High risk in soft soil excavation and impact on surrounding facilities

In the soft soil foundation environment, deep foundation pit excavation is likely to lead to large-scale settlement and displacement, which in turn will hurt municipal facilities, underground pipelines, and surrounding buildings, and even endanger structural safety.

Large-scale foundation pits and many challenges in the design and construction of the support system

Some deep foundation pits are large-scale with a vast excavation area, and their length and width can reach hundreds of meters. This undoubtedly increases the difficulty of the design and construction of the support system and puts forward higher requirements for the bearing capacity and stability of the support structure.

In the wave of technological iteration, self-drilling anchor bolts have emerged, providing a new solution for deep foundation pit support with their unique design concept and structural composition.

Introduction to Self-drilling Anchor Bolts

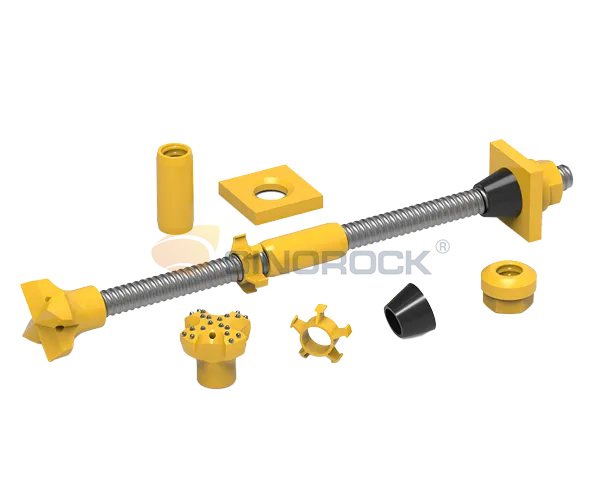

As an innovative achievement in the field of anchoring technology, self-drilling anchor bolts can overcome anchoring problems under complex geological conditions. Compared with traditional anchoring technology, self-drilling anchor bolts support construction has broken through the difficulties of hole formation and anchoring in loose and broken strata.

Its core design concept is to integrate functions such as drilling, grouting, and anchoring. Optimizing the construction process significantly reduces the construction difficulty and greatly improves the anchoring efficiency, providing an efficient and reliable solution for engineering projects.

Application Advantages of Self-drilling Anchor Bolts in Deep Foundation Pit Support

Significantly improve construction efficiency

In the construction of deep foundation pit support, time is cost and a guarantee of safety. Self-drilling anchor bolts integrate drilling, grouting, and anchoring. The self-drilling hollow anchor bar serves multiple functions as a drill rod, a grouting pipe, and an earth pressure-bearing body. There is no need to switch between multiple processes as in traditional anchor construction, which greatly saves construction time. This construction mode makes the construction process more efficient, especially suitable for deep foundation pit projects with tight schedules, which can effectively speed up the project progress and reduce time costs.

Well adapted to complex stratum conditions

The geological conditions of deep foundation pits are complex and changeable. Especially when encountering soft soil layers, soft surrounding rocks, and other formations that are difficult to drill or prone to hole collapse, traditional anchoring technology is often helpless. Self-drilling anchor bolts solve this problem with their unique advantages. After drilling, the self-drilling hollow anchor bar remains in the hole without being withdrawn, eliminating the trouble caused by hole collapse and significantly reducing the construction difficulty. In the face of complex and changeable geological conditions, self-drilling anchor bolts can stably play an anchoring role, showing strong stratum adaptability.

Flexible response to construction requirements

The on-site conditions of deep foundation pit support projects vary widely. The full-length threaded design of self-drilling anchor bolts gives them high flexibility. They can be cut off at any position and lengthened through couplers according to actual construction needs, which makes them easily adaptable to the support requirements of foundation pits with different depths and shapes. In addition, the drill bits of self-drilling anchor bolts have unique advantages and can be widely used in various stratum conditions. Whether it is hard rock or loose soil, they can ensure the smooth progress of the drilling process, further enhancing the application scope and adaptability of self-drilling anchor bolts in deep foundation pit support.

Ensure the anchoring effect

The anchoring effect is directly related to the safety and stability of deep foundation pit support. The threaded design of self-drilling anchor bolts enables them to be firmly connected with the couplers and form a good bond with the grouting body. During the grouting process, the grout fills from the bottom of the hole upwards, ensuring full grouting and high compactness, thus effectively improving the grouting quality.

High-quality grouting not only enhances the bond between the self-drilling anchor bolts and the rock and soil mass but also significantly improves the anchoring strength, enabling self-drilling anchor bolts to bear the lateral pressure of the soil in the deep foundation pit and provide stable support for the foundation pit slope and the surrounding environment, ensuring the safe construction of the deep foundation pit project.

Simplify the construction process

Compared with conventional anchor construction, the construction process of self-drilling anchor bolts is faster and simpler, especially suitable for deep foundation pit projects with limited construction space. The high-strength couplers combined with the lengthening feature of the self-drilling hollow anchor bar can complete the construction of long anchor bolts in a limited space, reducing the construction difficulty, improving the construction efficiency, and also reducing the investment in labor and equipment, achieving both economic benefits and construction convenience.

Conclusion

In conclusion, self-drilling anchor bolts, with their unique technical advantages, have shown great application potential in deep-foundation pit support projects, providing a reliable guarantee for the safe and efficient construction of deep-foundation pit projects.