In the thriving environment of the global construction industry, geotechnical anchoring technology has become increasingly important in various construction projects and has already become the key to ensuring the stability and safety of engineering structures.

As a highly efficient and innovative support material in geotechnical anchoring, self-drilling anchor bolts have been extremely widely used in various projects due to their unique advantages. From infrastructure construction to resource extraction projects, self-drilling anchor bolts can play a key role, in providing stable support, enhancing construction safety, controlling costs, and achieving excellent cost-effectiveness.

Next, let’s take an in-depth look at the specific applications of self-drilling anchor bolts in the six major categories of construction projects and explore how they excel in different scenarios.

Introduction to Self-drilling Anchor Bolts

Before exploring their applications, you may wonder—what exactly is a self-drilling anchor bolt? Next, I will provide a detailed professional overview of the origin, definition, and components of self-drilling anchor bolts.

Origin

The practice of stabilizing rock formations with anchor bolts has a long history. Initially, people used wooden beams and other materials for temporary support.

At the end of the 19th century, steel rock anchor bolts were introduced in the mining industry. The method involved drilling holes in the rock, inserting steel bars, and then fixing them with grouting or resin, which was a significant leap in rock reinforcement technology.

Since then, rock anchor bolt technology has undergone continuous improvements.

In the middle of the 20th century, fully-threaded rock anchor bolts emerged, enhancing the shear and tensile resistance capabilities.

However, traditional rock anchor bolts required specialized drilling equipment, and the installation process had multiple steps, which was time-consuming and labor-intensive.

To meet the demand for efficient and low-cost rock support, the industry innovatively introduced self-drilling anchor bolts. They integrate the functions of drilling and anchoring, simplifying the installation process and shortening the construction period, bringing another major breakthrough in rock anchor bolt technology.

Definition

Self-drilling anchor bolts, as an innovative achievement in the field of anchoring technology, are specifically designed to deal with complex geological conditions. When faced with loose, collapsible soils and fractured rock formations, traditional anchoring methods often fall short.

Self-drilling anchor bolts, however, stand out. With a unique design that integrates drilling, grouting, and anchoring functions, they simplify the construction process, reduce construction difficulty, and greatly improve the anchoring efficiency.

They provide a convenient, practical, and efficient anchoring solution for engineering projects, effectively ensuring the stability and safety of projects in complex geological environments.

Composition

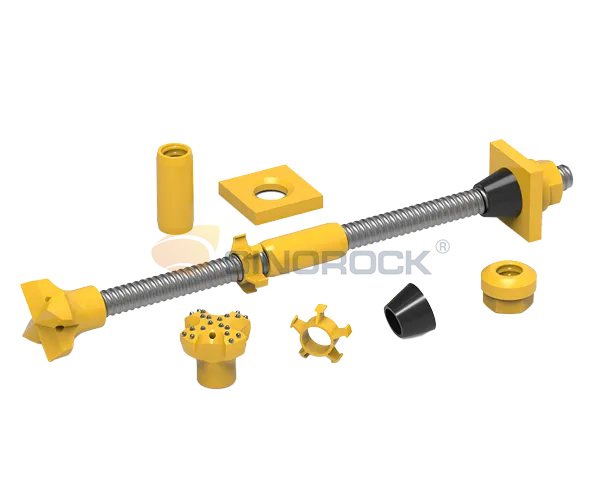

Self-drilling anchor bolts consist of six core components, and these components work together to achieve efficient anchoring functions:

- Self-drilling Hollow Anchor Bar: Made of high-quality alloy steel, the hollow structure allows for both drilling flushing and synchronous grouting. The left/right-hand thread design is compatible with standard drilling tools. The large pitch and deep tooth profile enable arbitrary cutting and extension. Its flexural strength is superior to that of solid bars.

- Drill Bit: Available in hardened and tungsten carbide types, it is suitable for different geological conditions. As a disposable consumable, it remains in the hole after drilling is completed, ensuring hole-forming efficiency.

- Coupler: It is used to extend the length of the bar and transmit torque. The precise design ensures sealing performance and energy transmission efficiency.

- Centralizer: It fixes the anchor bolt in the center of the borehole, ensuring the uniformity and compactness of grouting and prolonging the service life of the structure.

- Plate: It distributes the stress of the anchor bolt to the surface of the rock and soil, enhancing the friction and bite force at the contact surface.

- Nut: It cooperates with the domed plate to lock the anchor bolt, applying prestress to suppress deformation and improve the bearing capacity.

- Through the integration of the functions of each component, drilling, grouting, and anchoring can be completed simultaneously, significantly improving the construction efficiency and safety performance of projects in complex geological conditions.

- Through the above introduction, you should now have a clear understanding of the basic concepts and components of self-drilling anchor bolts. In actual engineering applications, self-drilling anchor bolts play a key role in the field of geotechnical anchoring due to their unique characteristics and significant advantages. Next, let’s explore the excellence of self-drilling anchor bolts from multiple dimensions.

Main Characteristics and Advantages of Self-drilling Anchor Bolts

Strengthen Bonding and Structural Stability

Self-drilling anchor bolts can bond closely with the surrounding rock mass, enhancing overall stability, preventing rock displacement and collapse, reducing safety risks, and improving the integrity of the surrounding rock structure.

Stabilize Unstable Strata

In areas with unstable strata, they can produce a suspending effect. By applying pre-pressure to the hollow anchor bolts, the frictional resistance between rock layers is increased, preventing the separation and sliding of layered rock masses.

Enhance Shear Resistance Support

They can provide stronger shear strength, effectively preventing the sliding between strata. The combination of the shear strength and frictional force formed by the anchor bolts enables them to withstand high stress, making them suitable for high-pressure environments such as tunnels and mines.

Continuously Increase Support Force

Self-drilling anchor bolts can continuously increase the support force over time. They can adjust the tension according to the settlement or deformation of the surrounding rock mass, providing long-term stability for the structure in a dynamic environment.

Ensure Roof Safety

In tunnel and underground construction, they can prevent the separation and detachment of the roof, providing early reinforcement, reducing accident risks, and decreasing long-term maintenance requirements.

Cost Saving

With a hollow design, they use less material than solid anchor bolts, resulting in high material usage efficiency and low cost. Moreover, due to their lightweight, they are easy to handle and install, saving on-site labor costs and time, making them an economical choice for large-scale projects.

Improve Construction Efficiency

The installation is simple, allowing workers to install more anchor bolts in a short time, accelerating the construction progress, shortening the project duration, and improving profitability and customer satisfaction.

Reduce Labor Intensity and Ensure Safety

They are lighter and easier to handle, reducing the auxiliary traffic volume and labor intensity on construction sites, decreasing the demand for additional equipment and transportation, and reducing congestion and accident risks, creating a safer working environment.

After a detailed analysis of the advantages of self-drilling anchor bolts, I believe you have a relatively thorough understanding of their excellent performance.

To further enhance your understanding of the practical applications of self-drilling anchor bolts, we will now conduct a professional, in-depth analysis of their construction process, demonstrating their use in engineering projects.

Construction of Self-drilling Anchor Bolts

Pre-construction Preparations

- Site Assessment and Geological Survey: Conduct a comprehensive geological survey to understand rock formations, soil conditions, groundwater levels, etc., providing a basis for judging slope stability and designing control schemes.

- Risk Identification: When assessing the site, consider both geological and environmental factors, such as vegetation, habitats, water bodies, etc. Identify potential risks and formulate response strategies to protect the ecological environment.

- Design Considerations

- Engineering Calculations and Analyses: Perform engineering calculations on slope stability and bearing capacity to support the design of slope control structures.

- Survey Work: Follow these key points – measure at multiple points on the slope to comprehensively collect data; carefully protect each survey stake; focus on protecting key and vulnerable stake points to ensure the accuracy of the structure.

- Construction Method Selection: Based on the assessment and analysis results, select the construction method for slope stabilization, such as installing retaining walls and temporary supports. Implement protective measures during construction to prevent accidents. At the same time, comprehensively consider factors such as cost, environment, and progress.

Factors to Consider during Construction

Loose Rocks and Anchoring: Loose rocks are likely to fall during cleaning, so be careful during anchoring construction. Take protective measures and cleanup in advance to prevent falling rocks from causing injuries.

- Safety in Slag Yard and Framework Operations: When working in the slurry pond and framework, pay attention to safety and operate in accordance with regulations to prevent falls.

- Construction Collaboration and Temporary Support: Workers should cooperate closely. Do not remove the temporary support before the steel frame and self-drilling anchor bolts are firmly connected.

- Grouting Pressure and Nozzle Safety: Keep a close eye on the pressure gauge during grouting. Reduce the pressure if it is too high, and never point the nozzle at people.

- Strictly Follow Operating Procedures: Strictly follow the operating procedures to avoid violations and reduce accident risks.

Construction Process

The construction technology of self-drilling anchor bolts is designed to deal with complex geological conditions and ensure the accuracy, strength, and stability of anchoring. The specific process is divided into six steps:

- Surveying, Setting-out, and Positioning: Before construction, accurately determine the position of the self-drilling anchor bolts according to the design requirements and clearly mark the vertical and horizontal spacing on-site to ensure that the layout of the self-drilling anchor bolts comply with the design specifications and achieves the best support effect.

- Installation of Anchor Bolts and Drill Bits: Select a suitable rock bolt drilling rig, such as the KW180 series. Use the hollow anchor bar as the drill pipe and install a Tungsten Carbide Drill Bit at its front end. This drill bit can effectively penetrate various rocks and soils and is equipped with small holes for subsequent grouting operations.

- Drilling: According to the pre-marked positions, accurately adjust and position the drilling rig and start drilling. During the drilling process, strictly control the drilling angle and depth to make them meet the design standards. Surveyors need to monitor in real-time to confirm the alignment accuracy of the anchor bolt position and the drilling rig, ensuring the accuracy of the drilling.

- Extending the Bar: For deeper foundation pits, if a single hollow anchor bar cannot meet the depth requirements, use couplers to connect multiple sections of bars. If the anchor bolt needs to pass through the free soil section, put protective PVC bellows on its outside to prevent the anchor bolt from being corroded or damaged during grouting and tensioning.

- Grouting: Grouting is a key link to enhance the bonding strength between the anchor bolt and the surrounding rock and soil mass. Use pure cement grout as the grouting material and high-pressure grouting equipment to inject the grout into the hollow bar, ensuring that the grout spreads evenly and fills the voids around the anchor bolt to avoid air pockets or weak areas. The grouting pressure should be maintained above 1.5MPa to make the grout fully penetrate into the cracks and fissures of the surrounding strata, improving the overall strength of the anchoring system.

- Tensioning and Locking: After the grout has solidified and reached the design strength, use professional tensioning equipment to apply the predetermined tension to the anchor bolt, and then install the support plate and locking nut to complete the system locking. The tensioning process further strengthens the bonding between the anchor bolt and the surrounding materials, enhancing the overall stability of the foundation pit foundation.

After a detailed understanding of the construction process, you should now have a clear grasp of the working principle of self-drilling anchor bolts. From drilling, and inserting to anchoring, each step of meticulous operation forms the basis for its function.

Next, let’s enter the “battlefield” of self-drilling anchor bolts explore in-depth their key applications in various scenarios, and see how this efficient anchoring tool shines in different situations.

Applications of Self-drilling Anchor Bolts in Various Construction Projects

Slope Engineering

Slope engineering is extremely challenging, especially for high slopes with a height of more than 30 meters, and even ultra-high slopes of more than 100 meters. Usually, a combined reinforcement system of self-drilling hollow anchor bolts and fully-bonded anchor bolts, together with local reinforcement technologies, is adopted to maintain slope stability.

Self-drilling hollow anchor bolts, with high strength and good adaptability, can effectively distribute loads, prevent soil erosion and slope degradation, and play an important role in key infrastructure projects such as transportation, water conservancy, hydropower, and urban geotechnical slope protection, effectively ensuring the service life of these projects.

Tunnel and Underground Engineering

Tunnel and underground cave projects require a solid support system to reduce the risks of settlement and sidewall displacement. Currently, the method of using self-drilling hollow anchor bolts and system mortar anchor bolts for reinforcement, combined with reinforced shotcrete, has become a common approach to ensure the stability of the surrounding rock in complex environments.

This reinforcement method can effectively reduce roof settlement and sidewall displacement, not only ensuring the structural stability of tunnels and underground caves but also improving personnel safety and protecting assets during project construction. Self-drilling hollow anchor bolts have become the standard configuration in the industry due to their reliability and efficiency.

Coal Mining Project

In coal mining projects, safety and stability are of utmost importance, and self-drilling hollow anchor bolts play a core role. They are often used in combination with shotcrete support to reinforce the surrounding rock. According to statistics, approximately 5,000 kilometers of roads are supported by this method every year. Self-drilling hollow anchor bolts have significant advantages in the complex underground environment of coal mines. They can provide strong reinforcement, ensure the structural integrity of tunnels and passages, and greatly improve the safety and production efficiency of coal mining operations worldwide.

Foundation Engineering

In urban construction, foundation pits are common, and self-drilling hollow anchor bolts are crucial as pile foundation support structures. Due to the high requirements for ultimate tensile force and drilling depth, large-diameter self-drilling hollow anchor bolts that can withstand huge pressure are needed.

These anchor bolts can reach an ultimate tensile force of up to 1900kN, creating a solid foundation for high-rise buildings and ensuring the stability of foundation pits. This not only complies with strict urban construction safety standards but also enhances the durability and service life of buildings.

Water Conservancy and Hydropower Dam Engineering

Dam projects face unique challenges as they need to prevent floods and ensure long-term stability. Self-drilling hollow anchor bolts are a key solution.

They can fix the main body of the dam to the bedrock and reinforce or upgrade the dam without affecting its normal operation, greatly reducing construction costs and minimizing downtime. Dams bear huge pressure, and the requirement for the tensile force value of anchor bolts is high.

For example, in the Shiquan Dam project, 29 anchor bolts with a tensile force value of 6000kN were used, and there are also anchor bolts with a tensile force value as high as 8000kN, fully demonstrating the great strength of self-drilling hollow anchor bolts and their applicability in key infrastructure projects.

Anti-floating Engineering

In anti-floating engineering, self-drilling anchor bolts serve as anti-floating anchor bolts, which can improve the utilization rate of soil layer strength and enhance the durability of anchor bolts.

Anti-floating anchor bolts have various configurations, such as point-like concentrated layout, linear concentrated layout, and planar uniform layout, and can provide customized solutions according to specific construction problems.

Using self-drilling hollow anchor bolts in anti-floating engineering can not only ensure the stability of the foundation but also improve the long-term performance and safety of the structure, effectively resisting potential risks caused by soil instability and foundation movement.

Future Prospects and Expectations of Self-drilling Anchor Bolts

With the vigorous development of the global construction industry and the continuous advancement of various infrastructure construction and resource extraction projects, self-drilling anchor bolts, with their unique advantages, show extremely broad future prospects in the field of construction engineering.

Continuous Expansion of Application Fields

Based on their current applications in six major categories of construction projects, with the increasing demand for geotechnical anchoring technology in more emerging fields, self-drilling anchor bolts are expected to enter new markets.

For example, in the construction of deep-sea subsea tunnels, the characteristics of self-drilling anchor bolts, which integrate drilling, grouting, and anchoring functions, can effectively cope with complex geological conditions and construction environments, providing stable support for these high-difficulty projects.

Prominence of Green and Environment-friendly Advantages

Against the backdrop of the global advocacy for green buildings and sustainable development, the advantages of self-drilling anchor bolts, such as material conservation, high construction efficiency, and low labor intensity, will be more in line with environmental protection concepts.

Their hollow design reduces material consumption and energy consumption; efficient construction shortens the construction period, reducing resource waste and environmental pollution.

This will make them more favored in future construction projects and become one of the preferred anchoring materials for green building construction.

Steady Growth of Market Demand

With the acceleration of urbanization, the number of high-rise buildings and underground space development projects in urban construction is increasing, and the requirements for the stability of foundation and subgrade engineering are also getting higher and higher.

As a key anchoring material, the market demand for self-drilling anchor bolts will continue to rise. In addition, in transportation infrastructure construction, such as highway and railway tunnel projects, self-drilling anchor bolts will also play an important role, further promoting the expansion of their market scale.

Conclusion

In summary, self-drilling anchor bolts (SDA Bolts) in modern construction, as an innovative achievement have evolved from traditional anchor bolt technology. With their unique design, significant advantages, and wide applicability, they have already occupied a pivotal position in various current construction projects. From careful preparations before construction, and rigorous operations during construction, to efficient applications in different construction scenarios, they fully demonstrate their excellent performance.

Looking to the future, with the continuous progress of science and technology and the increasing social demands, self-drilling anchor bolts will not only break new ground in emerging fields to meet the needs of more complex engineering projects but also be more favored by the market due to their compliance with green and environmental protection concepts.

It is believed that on the broad stage of the future construction industry, self-drilling anchor bolts will shine more brightly and continuously inject a strong impetus into the vigorous development of the global construction industry.