Introduction

Self-drilling rock bolts are a key component in modern geotechnical engineering, particularly for tunnel support, slope stabilization, and mining applications. These bolts are designed to be installed without the need for pre-drilling a hole, allowing them to anchor securely into the ground or rock formations. The question of whether self-drilling rock bolts can be installed into a variety of different soils is crucial for engineers and contractors working on diverse projects. Understanding the soil types, installation techniques, and potential challenges is key to successfully using self-drilling rock bolts in varying ground conditions.

This article will explore the installation of self-drilling rock bolts in different soils, the challenges involved, and the solutions that make these bolts an effective option for geotechnical applications across various soil conditions.

Understanding Self-Drilling Rock Bolts

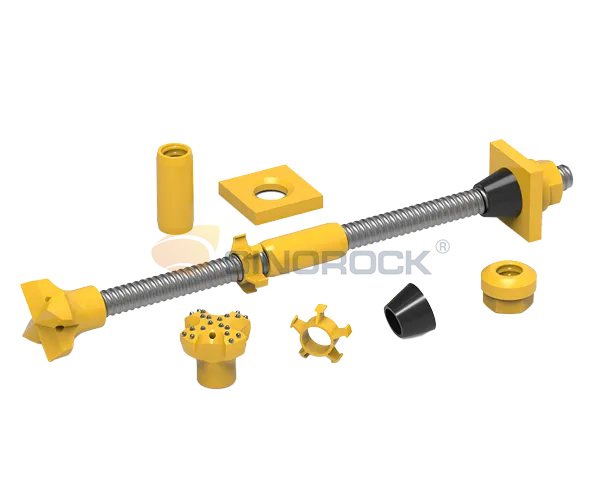

Self-drilling rock bolts are essentially a combination of a drill bit, a bolt, and a grout pipe that are all integrated into a single unit. The installation process involves drilling the bolt directly into the ground or rock using the bolt itself as the drilling tool. Once installed, the bolt is grouted into place, providing support to the surrounding soil or rock.

These bolts are widely used for stabilization purposes in tunnels, mines, and slopes. They are especially effective in areas where traditional bolting methods are not feasible due to challenging ground conditions.

How Do Self-Drilling Rock Bolts Work?

The key feature of self-drilling rock bolts is their ability to combine drilling and bolting into a single process. The bolt itself functions as both the drill rod and the anchor, allowing it to create a hole and secure itself into place. Once the bolt is drilled into the soil or rock, it is grouted to provide a solid anchor that resists movement and maintains stability. The process is fast and efficient, reducing the need for separate drilling and bolting steps.

Types of Soils and Their Characteristics

To understand how self-drilling rock bolts perform in different soils, it’s important to first explore the types of soils typically encountered in geotechnical projects. Each soil type has unique characteristics that can impact the performance and installation of rock bolts.

Cohesive Soils (Clay and Silt)

Cohesive soils, such as clay and silt, are known for their ability to stick together due to their fine particles and strong cohesion. While this can make them stable and supportive, it can also make drilling more difficult. Clay soils can be soft and prone to swelling when exposed to water, which can affect the installation process and long-term performance of the rock bolt.

Non-Cohesive Soils (Sand and Gravel)

Non-cohesive soils, including sand and gravel, are less stable and more prone to shifting. These soils have lower cohesion, making them more challenging for anchor bolts to secure. However, self-drilling rock bolts are still highly effective in these conditions if the proper installation techniques are used. Loose sand and gravel can present a risk of the bolt becoming unstable over time, especially if groundwater is present.

Rocky or Hard Soils

Hard rock formations present their own set of challenges when installing self-drilling rock bolts. While these conditions typically offer more stability, drilling into hard rock requires special equipment and techniques. Self-drilling bolts can still be used effectively in these conditions, but the equipment and installation speed may differ compared to softer soils.

Installation of Self-Drilling Rock Bolts in Different Soils

The installation process for self-drilling rock bolts can vary depending on the soil type. Let’s examine how these bolts perform in different soil conditions.

Installing Self-Drilling Rock Bolts in Cohesive Soils (Clay)

In clay-rich soils, the self-drilling rock bolt installation process tends to be more straightforward. However, challenges such as soil swelling or water retention can complicate the process. To mitigate these issues, it’s important to monitor the moisture content of the soil during installation, as wet clay can cause the hole to collapse. In some cases, the addition of stabilizing agents or sealants may be necessary to ensure the bolt remains secure.

Installing Self-Drilling Rock Bolts in Non-Cohesive Soils (Sand and Gravel)

Installing self-drilling rock bolts in non-cohesive soils like sand and gravel can be more challenging. These soils are loose and may shift under pressure, which can cause instability in the bolt. To address this, installers often use specialized grout materials to improve bond strength. Additionally, self-drilling bolts with enhanced anchoring capabilities may be used to better secure the bolt in these conditions.

Installing Self-Drilling Rock Bolts in Rocky or Hard Soils

When working with hard rock formations, self-drilling rock bolts may require more advanced drilling techniques. In some cases, pilot holes may need to be pre-drilled to assist with the installation process. These bolts provide strong support once installed but require specialized equipment to handle the tough materials they are embedded in.

Soil-Dependent Challenges and Solutions

There are several challenges to consider when installing self-drilling rock bolts in different soil types. Fortunately, each challenge has corresponding solutions that can ensure the effectiveness of the installation process.

Dealing with Water Content and Swelling Soils

Cohesive soils, particularly clay, can swell when exposed to water, causing the drilled hole to close and preventing the bolt from being properly anchored. To overcome this, engineers may use water-resistant grouts or apply a sealing agent around the bolt after installation.

Overcoming Difficulty in Anchoring Bolts in Loose or Granular Soils

In loose or granular soils, such as sand or gravel, the challenge lies in securing the bolt to prevent shifting. The use of high-quality grout and grout injection techniques can help stabilize the surrounding soil, increasing the bond between the bolt and the ground.

Solutions for Uneven or Fractured Rock Formations

When working with fractured rock, ensuring proper bolt alignment can be difficult. Specialized bolts with greater anchoring capacity can help improve performance in fractured or uneven rock, providing greater stability.

Benefits of Using Self-Drilling Rock Bolts in Various Soil Types

Self-drilling rock bolts offer numerous advantages that make them suitable for a wide range of soil types.

Cost-Effectiveness and Versatility

Self-drilling rock bolts reduce the need for separate drilling and bolting operations, cutting down on both equipment and labor costs. Their versatility allows them to be used in a variety of soil conditions, making them a valuable tool in geotechnical engineering projects.

Reduced Installation Time

Because self-drilling rock bolts combine the drilling and bolting process, installation is much faster compared to traditional methods. This results in shorter project timelines and reduced overall project costs.

Increased Safety and Stability

Self-drilling rock bolts provide enhanced safety and stability by securely anchoring the surrounding soil or rock. Their ability to be installed in various soil types means that they can help stabilize unstable slopes, tunnels, and other geotechnical structures.

Long-Term Performance

Once installed, self-drilling rock bolts offer long-term performance and durability. The grout around the bolt ensures a stable bond, while corrosion-resistant coatings enhance their longevity in harsh environments.

Conclusion

In conclusion, self-drilling rock bolts can be installed into a variety of different soils, including cohesive soils like clay, non-cohesive soils like sand and gravel, and even rocky or hard soils. The installation process may vary depending on the soil type, but with the right techniques and equipment, self-drilling rock bolts provide an efficient, cost-effective, and reliable solution for geotechnical applications.

As technology advances, self-drilling rock bolts will continue to play a crucial role in the stabilization and support of infrastructure projects, making them a go-to option for engineers and contractors working in diverse ground conditions.