Introduction: The Growing Complexity of Foundation Pit Engineering

With the rapid development of modern construction projects, foundation pits are being excavated to unprecedented depths, often penetrating into increasingly complex geological formations. The deeper and more complex these formations become, the more challenging it is to ensure the safety and stability of foundation pits. Among the most difficult conditions encountered in foundation engineering are quicksand layers, commonly found in areas near water bodies such as rivers, seas, or areas with high groundwater levels. These quicksand layers present significant challenges, especially in the construction of anchor systems for foundation pit support.

This article will provide a comprehensive overview of the difficulties encountered when constructing anchors in quicksand layers, followed by a detailed discussion of how self-drilling rock bolts provide an effective solution to these challenges. We will also explore the various steps involved in constructing self-drilling rock bolts in quicksand layers, from preparation to testing.

1. The Challenges of Anchor Construction in Quicksand Layers

Before diving into the solution, it’s crucial to understand the specific difficulties that quicksand layers present during anchor construction. This will help to illustrate why traditional methods often fall short and why more advanced techniques, such as using self-drilling rock bolts, are necessary.

1.1 Containing Groundwater

One of the most defining characteristics of quicksand layers is their high groundwater content. Quicksand is a loose, sandy soil layer with a fluid-like state due to its uniform sand particle size and large porosity. The high permeability of this layer allows water to flow freely, creating an unstable foundation for construction. The presence of groundwater in these layers poses significant risks to construction projects, including potential landslides and foundation failures.

In areas with abundant groundwater, water management becomes a primary concern. Without proper measures to block sand and divert water, the quicksand layer can destabilize surrounding soil, leading to catastrophic events such as landslides or sinkholes. Furthermore, as groundwater flows through the quicksand layer, it can carry sand particles away, resulting in erosion and the subsequent collapse of the foundation.

1.2 Thixotropy

Quicksand layers, especially those consisting of clay, possess thixotropic properties. Thixotropy refers to the quicksand’s ability to change from a solid-like state to a liquid-like state when subjected to mechanical vibrations. This transformation can occur rapidly, and the fluidity of the quicksand increases with higher vibration frequencies.

During construction, vibrations from drilling, machinery, or other activities can trigger the quicksand layer to behave like a liquid, causing significant instability. The flow of the liquefied sand can undermine the structural integrity of the foundation pit, potentially leading to collapse. Managing the thixotropic behavior of quicksand is a critical challenge in foundation pit support projects.

1.3 Collapse of Holes

One common approach to dealing with quicksand layers is the use of casing support. While this method can provide some stability, it comes with its own set of challenges. As the depth of the hole increases, the casing becomes susceptible to bending and other deformations. When the casing is withdrawn, the surrounding quicksand layer often collapses into the hole, leading to additional difficulties in construction.

This collapse not only makes further drilling and anchor installation challenging but can also endanger nearby structures and workers. In severe cases, the collapse of the hole can cause the foundation pit to become unstable, compromising the safety of the entire project.

1.4 Pull-out Resistance Issues

Even if anchor construction in a quicksand layer is successfully completed, there is often an issue with the pull-out resistance of the anchors. In many projects, the pull-out bearing capacity fails to meet the design standards, which can have severe implications for the stability and safety of the foundation pit.

This problem is usually caused by the collapse of the anchor hole after the casing is withdrawn, which leads to a reduction in the amount of anchor slurry consumed. As a result, the anchor body cannot form a strong bond with the surrounding soil, diminishing its ability to provide adequate support. Without sufficient pull-out resistance, the anchor system may fail to secure the foundation pit adequately.

2. The Self-Drilling Rock Bolt: A Solution for Quicksand Layer Construction

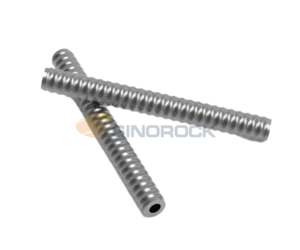

Given the numerous challenges presented by quicksand layers, traditional anchor construction methods are often inadequate. However, self-drilling rock bolts offer a more effective solution, especially in quicksand layers where conventional techniques struggle. Self-drilling rock bolts are designed to integrate drilling, anchoring, and grouting into a single process, which significantly improves construction efficiency and the stability of the foundation.

Here is a step-by-step guide on how self-drilling rock bolts can be effectively used in quicksand layer construction.

2.1 Construction Preparation

Proper preparation is essential before commencing any construction in quicksand layers. The working surface must be flat and solid to ensure the drilling rig remains stable during construction. Since quicksand layers contain groundwater, this added weight and movement could cause the rig to shift or even sink if the surface isn’t adequately prepared.

To mitigate these risks, the working surface should be at least six meters wide. This ensures ample space for the drilling equipment, personnel, and self-drilling rock bolts, minimizing the risk of accidents and delays. Additionally, drainage ditches should be dug around the foot of the slope to manage groundwater effectively, preventing the quicksand from becoming even more fluid.

2.2 Positioning the Rock Bolts

Accurate positioning is crucial for the effectiveness of self-drilling rock bolts. Before construction begins, measurements should be taken to ensure the anchors are placed according to the design specifications. During the positioning process, it’s essential to account for the fact that sand, mud, and cement slurry will flow out of the anchor hole during drilling.

To prevent the anchor holes from becoming clogged, it is recommended that the self-drilling rock bolts be positioned 200-300mm away from the bottom of the pit. This spacing allows for better management of the debris produced during drilling and reduces the risk of obstruction, ensuring a more efficient installation process.

2.3 Drilling and Grouting

One of the key advantages of self-drilling rock bolts is their ability to perform drilling and grouting simultaneously. In the quicksand layer, this feature is particularly beneficial because it allows for the continuous stabilization of the surrounding soil as the anchor is installed.

During the drilling process, it’s essential to monitor the inclination angle of the anchor rod closely. The inherent instability of the quicksand layer can cause deviations from the design specifications, so adjustments may be needed to ensure the drilling is carried out correctly. Grouting while drilling helps to strengthen the soil, increasing the bonding strength between the anchor and the surrounding soil, which in turn improves the overall bearing capacity of the anchor system.

2.4 Secondary Grouting

Due to the high permeability and loose structure of quicksand layers, a large amount of grout is typically consumed during the initial grouting process. To compensate for this, a secondary grouting phase is necessary.

Once the anchor body has reached a certain level of strength, high-pressure grouting is performed a second time. This secondary grouting process ensures that any voids created by the initial grout absorption are filled, further strengthening the bond between the anchor and the soil. Secondary grouting is a critical step in achieving the required pull-out resistance for the anchor system.

2.5 Fixation

After drilling and grouting are complete, it’s crucial to ensure that the anchor rod is securely fixed in place. Any leakage at the anchor hole should be filled with grout to prevent further movement of the rod. Once the grout has set, a pad and nut are installed on the self-drilling hollow anchor bar to secure the rod in place.

During the maintenance period, it is essential to avoid any movement or displacement of the rock bolts, as this can compromise the integrity of the anchor system. Proper fixation ensures that the self-drilling rock bolts will provide long-term support to the foundation pit, even in the challenging conditions of a quicksand layer.

2.6 Testing for Pull-out Resistance

The final step in the construction process is testing the tensile resistance of the self-drilling rock bolts. This is done by randomly selecting 5% of the total number of anchors for testing. The tensioning equipment must be calibrated beforehand to ensure accurate results.

To avoid interference between adjacent anchors, the interval tensioning construction method is used. This method ensures that each anchor is tested in isolation, providing a clear measure of its tensile resistance. Successful pull-out tests confirm that the anchor system is capable of meeting the design requirements for the project.

3. Why Self-Drilling Rock Bolts Outperform Traditional Anchors in Quicksand Layers

The use of self-drilling rock bolts in quicksand layers offers several advantages over traditional anchor systems. One of the most significant benefits is their ability to achieve a pull-out force approximately 30% higher than that of ordinary anchor bolts. This improved performance is due to the unique design of self-drilling rock bolts, which allows for simultaneous drilling and grouting, as well as the ability to perform secondary grouting to strengthen the anchor bond.

In addition to their superior pull-out resistance, self-drilling rock bolts are also more efficient to install, reducing the time and labor required for construction. This makes them an ideal solution for projects that face tight deadlines or challenging environmental conditions.

Conclusion: A Reliable Solution for Complex Geological Conditions

Construction in quicksand layers poses unique challenges, but with the right approach and equipment, these challenges can be overcome. Self-drilling rock bolts offer a reliable and effective solution for supporting foundation pits in quicksand layers, ensuring the stability and safety of the project.

If you are facing difficult geological conditions or are interested in learning more about self-drilling rock bolts, contact Sinorock. Our team of experts can provide customized solutions tailored to your specific project needs, helping you achieve success.