For a long time, rock bolts have been used to reinforce and support underground excavations in both civil and mining engineering. According to their anchoring mechanisms, rock bolts can be classified into various groups. One prominent category is friction bolts, which provide support pressure through friction between the bolt shanks and the rock surfaces of drill holes. Among friction bolts, split sets are the first and most widely used type. This article delves into the intricate details of split set rock bolts, their applications, advantages, testing methods, and the parameters affecting their performance.

Understanding Split Set Rock Bolts

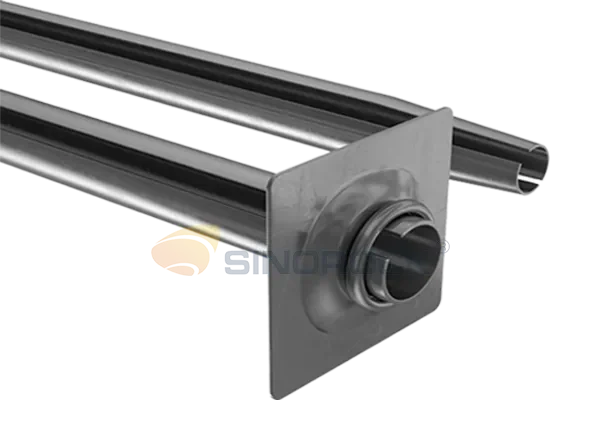

Split set rock bolts, consisting of a tube and a plate, are inserted into drill holes with slightly smaller diameters than the rock bolts themselves. This insertion generates a radial spring force due to the compression of the tube, which has a slit in its cross-section shaped like a “C”. The compression of the tube provides the frictional anchorage in drill holes, effectively securing the rock mass.

Components and Mechanism

The main components of a split set rock bolt include:

- Tube: A slotted steel tube that provides frictional contact with the rock surface.

- Plate: A bearing plate that transfers load from the rock mass to the bolt.

When a split set is driven into a drill hole, the slit in the tube compresses, generating frictional resistance along the contact surface between the tube and the rock. This frictional resistance is crucial for the bolt’s anchorage and overall performance.

Installation and Immediate Load-Bearing Capacity

One of the key advantages of split sets is their ability to start bearing load immediately upon installation. Unlike other types of rock bolts that require grouting or setting time, split sets provide immediate support, making them particularly useful in dynamic and unstable ground conditions. This immediate load-bearing capacity is essential in ensuring the stability of underground excavations and preventing collapses during the construction phase.

Advantages of Split Set Rock Bolts

Split set rock bolts are popular in rock engineering due to their numerous advantages:

Practical Application

Split sets are easy to install and do not require specialized equipment or complex procedures. This simplicity makes them a practical choice for various underground applications.

Immediate Load Bearing

As mentioned earlier, split sets can start bearing load immediately upon installation, providing immediate support and enhancing the safety of underground workings.

High Deformation Tolerance

Split sets maintain a close load-bearing capacity to their peak even under high deformations in tunnels. This characteristic is particularly beneficial in managing ground movements and ensuring long-term stability.

Continuous Support Pressure

Even when sliding occurs at the friction interface, split sets can provide consistent support pressure. This is achieved through the normal stress at the friction interface, the friction coefficient, and the friction bond length. The ability to maintain support pressure under sliding conditions makes split sets reliable in various ground conditions.

Length and Load-Bearing Capacity

The length of split sets is a critical parameter influencing their load-bearing capacity. Generally, split sets used in rock engineering range from 2 meters to 3 meters in length. However, depending on the site requirements, they can be applied in lengths varying from one meter to four meters.

Importance of Friction Bond Length

For effective support, the friction bond length should be sufficiently long. The load-bearing capacity of rock bolts increases with an increase in length. This is because a longer friction bond length provides more contact area for frictional resistance, enhancing the bolt’s anchorage.

Pull-Out Tests

A popular method to determine the load-bearing capacities of rock bolts is the pull-out test. This test evaluates the bearing capacities of rock bolts under axial loading conditions and verifies their effectiveness. During the test, split sets inserted into drill holes are held from the collars at the back ends of the tubes and pulled out by the hydraulic jack of the equipment. The axial load is applied to the rock bolts, and the load capacity is measured as the maximum load borne by the friction bond between rock and bolt surfaces. This maximum load is typically reached just before the steel tube of the split sets starts sliding.

Load and Displacement Behavior

Split set rock bolts exhibit a unique load and displacement behavior. After reaching the peak load, the bolts can continue to move by sliding in the drill holes under a slightly lower load. This behavior ensures that the bolts maintain a near-constant load level, providing ideal support reactions and a good energy absorption capacity.

Factors Affecting Performance

The performance of split set rock bolts is influenced by various factors, including:

Bolt Length

As discussed earlier, the length of the bolt is a critical parameter. Longer bolts provide more contact area for frictional resistance, enhancing the load-bearing capacity.

Material Strength

The strength of the bolt material also plays a significant role. The friction load-bearing capacity depends not only on the friction coefficient and stresses on the friction surface but also on the strength of the bolt material. If the bolt material yields or fails, the overall performance of the bolt is compromised.

Friction Coefficient and Normal Stress

The friction coefficient and normal stress at the friction interface are crucial for the bolt’s performance. Higher friction coefficients and normal stresses increase the frictional resistance, enhancing the bolt’s anchorage.

Critical Length

In cases where the friction bond length exceeds a critical length, the bolt steel may fail instead of sliding at the friction surface. Therefore, it is essential to optimize the bolt length to ensure that the friction load-bearing capacity is maximized without compromising the integrity of the bolt material.

Conclusion

Split set rock bolts play a crucial role in reinforcing and supporting underground excavations in both civil and mining engineering. Their practical application, immediate load-bearing capacity, high deformation tolerance, and continuous support pressure make them an essential component of underground support systems. The performance of split set rock bolts is influenced by various factors, including bolt length, material strength, friction coefficient, and normal stress.

As the industry continues to evolve, innovations such as enhanced materials, surface coatings, real-time monitoring, and sustainable practices are shaping the future of split set rock bolts. By understanding and optimizing these factors, engineers can ensure the safety and stability of underground excavations, contributing to the success of construction projects and the protection of workers.

In conclusion, split set rock bolts remain a fundamental tool in the field of rock engineering. Their ability to provide reliable support under varying conditions makes them indispensable in maintaining the integrity of underground structures. With ongoing advancements and a focus on sustainability, the future of split set rock bolts looks promising, offering enhanced performance and safety for underground engineering projects.