Introduction

Split set rock bolts represent a significant advancement in rock bolting technology, offering enhanced stability and support for surrounding rock formations. Unlike traditional rock bolts, split set rock bolts provide full-length anchorage and active reinforcement, making them highly effective in maintaining rock integrity in various geotechnical and construction applications. This article delves into the specifications, working principles, technical features, requirements, performance, and usage methods of split set rock bolts, providing a comprehensive understanding of their role in modern engineering projects.

Understanding Split Set Rock Bolts

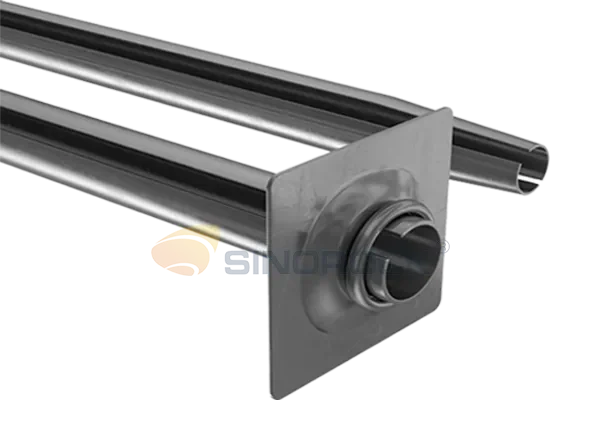

What Are Split Set Rock Bolts?

Split set rock bolts are high-strength steel pipes with a longitudinal slit, designed to be installed in drilled holes slightly smaller than the pipe’s diameter. When driven into the hole, the split set rock bolt exerts radial pressure along its entire length, coupled with friction and the bearing force of an anchor tray pallet. This triad of forces stabilizes the surrounding rock, preventing displacement and maintaining structural integrity even under dynamic conditions like blasting vibrations.

Specifications of Split Set Rock Bolts

The effectiveness of split set rock bolts hinges on their precise specifications, which include:

- Outside Diameter: Φ30, Φ33, Φ40, Φ43 (±0.5 mm)

- Length: 1200 mm, 1500 mm, 1800 mm, 2000 mm, 2500 mm

- Material: Q235, 16Mn, 20 Mnsi

These specifications ensure that split set rock bolts can be tailored to various applications, providing the necessary strength and stability.

Working Principle of Split Set Rock Bolts

The installation of a split set rock bolt involves inserting it into a borehole that is slightly smaller in diameter than the bolt itself. This installation process generates three key forces:

- Radial Pressure: Exerted along the entire length of the bolt, this pressure stabilizes the borehole wall.

- Frictional Force: Prevents the surrounding rock from sliding down, enhancing stability.

- Bearing Force: Provided by the anchor tray pallet, this force contributes to maintaining the surrounding rock in a stable, three-way force state.

By combining these forces, split set rock bolts ensure that the surrounding rock remains stable, even under dynamic conditions such as blasting vibrations or significant rock displacement.

Technical Features of Split Set Rock Bolts

Raw Material and Construction

Split set rock bolts are manufactured from high-strength alloy strip steel, ensuring durability and robustness. This material choice provides excellent resistance to deformation and corrosion, crucial for long-term applications in harsh environments.

Simple Installation

One of the standout features of split set rock bolts is their straightforward installation process. Unlike traditional rock bolts that require anchoring agents, split set rock bolts can be installed directly into pre-drilled holes using an impact drill. This simplicity not only reduces installation time but also minimizes labor costs.

High Friction and Strength

The design of split set rock bolts ensures high friction between the bolt and the rock body, which is essential for preventing rock movement. Additionally, these bolts exhibit high shear and tensile strength, making them capable of withstanding significant loads and stresses.

Uniform Force Distribution

Equipped with high-strength plates, split set rock bolts ensure uniform force distribution across the rock face. This uniformity is critical for maintaining stability and preventing localized failure.

Compatibility with Roadway Height

Split set rock bolts are designed to be compatible with the height of roadways, ensuring that they can be effectively used in various mining and tunneling applications.

Technical Requirements for Split Set Rock Bolts

To ensure optimal performance, split set rock bolts must meet specific technical requirements:

- Surface Quality: The bolt’s surface should be flat, free of serious strain, rust, and corrosion. The weld should be free of cracks, air holes, and slag, and should not burn through the bolt.

- Weld Quality: The retaining ring weld must withstand a pull-off force of ≥ 80kN, while the rod body should have an ultimate tensile force of ≥ 110kN.

- Anchor Force: The initial anchor force should be ≥ 25kN/m, and the plate bearing capacity should be ≥ 65kN.

Technical Performance of Split Set Rock Bolts

The technical performance of split set rock bolts is characterized by several key metrics:

- Initial Anchoring Force: Ranges from 3 to 7 tonnes.

- Pipe Ring Pull-Off Load: Ranges from 8 to 10 tonnes.

- Rock Bolt Pull-Off Resistance: Ranges from 12 to 13 tonnes.

- Corrosion Resistance: 20 to 30% higher than A3 steel, making split set rock bolts suitable for long-term use in corrosive environments.

Usage Method of Split Set Rock Bolts

The installation and usage of split set rock bolts involve several steps:

- Determine Anchor Hole Position: According to design requirements, identify the optimal position for the anchor hole.

- Drill the Hole: Use a drilling rig to create the borehole.

- Clean the Hole: Blow out rock powder from the hole using compressed air.

- Mount the Plate: Attach the plate to the rod body.

- Install the Rock Bolt: Drive the rock bolt into the hole using an impact drill.

Applications and Benefits of Split Set Rock Bolts

Mining and Tunneling

Split set rock bolts are extensively used in mining and tunneling operations to reinforce rock masses and prevent collapses. Their ability to provide immediate support makes them ideal for these dynamic and high-stress environments.

Construction Projects

In construction projects, split set rock bolts are employed to stabilize excavations, slopes, and retaining walls. Their high tensile and shear strength ensures that they can withstand the loads and stresses encountered in construction applications.

Geotechnical Engineering

Geotechnical engineers utilize split set rock bolts to enhance the stability of rock masses in various projects, including dams, bridges, and highways. Their corrosion resistance and long-term durability make them suitable for these critical applications.

Benefits of Split Set Rock Bolts

- Enhanced Stability: The combination of radial pressure, frictional force, and bearing force ensures superior rock stability.

- Cost-Effective Installation: The simple installation process reduces labor and material costs.

- High Load Capacity: The high shear and tensile strength of split set rock bolts make them capable of withstanding significant loads.

- Corrosion Resistance: Improved corrosion resistance extends the lifespan of the bolts, making them suitable for long-term applications.

- Versatility: Split set rock bolts can be used in a wide range of geotechnical and construction applications, making them a versatile solution for rock reinforcement.

Conclusion

Split set rock bolts represent a significant advancement in rock bolting technology, providing enhanced stability and support for surrounding rock formations in various geotechnical and construction applications. Their simple installation process, high load capacity, and improved corrosion resistance make them a cost-effective and reliable solution for rock reinforcement. By understanding the specifications, working principles, technical features, requirements, performance, and usage methods of split set rock bolts, engineers and construction professionals can effectively utilize them to ensure rock stability and safety in their projects.